Why are so many growers still sticking with HPS in the age of LED?

Anyone exploring the current indoor growing landscape will encounter a dominant narrative: the age of LED has arrived. Grow Tents and commercial facilities now gleam with the light of advanced diode panels, promoted as the pinnacle of efficiency and modernity. The general consensus seems clear: technologies like High Pressure Sodium (HPS) are relics destined to be forgotten. However, beneath the surface of this trend, a fascinating paradox persists: a significant and experienced segment of the growing community not only continues to use HPS luminaires but actively invests in them, achieving harvests of spectacular quality and weight.

This apparent contradiction raises a fundamental question: is this simple resistance to change, or is there a strategic logic behind this loyalty to HPS? It’s not about following trends, but about understanding the science of light, plant biology, and the economics of Cultivation to make informed decisions.

Beyond watts and lumens

To make a fair comparison, it is imperative to abandon an obsolete metric: the watt as a measure of light output. Comparing luminaires based solely on their electricity consumption is a fundamental error. For years, the industry has used lumens and lux, but these units measure light as perceived by the human eye, which is most sensitive to the green-yellow spectrum. In contrast, the photosynthetic engine of plants, chlorophyll, absorbs energy most efficiently in the blue and red regions of the spectrum. Judging a grow light by its lumens is like choosing food by its colour instead of its nutritional value.

Modern horticultural science uses metrics focused on the light that plants actually use. Photosynthetically Active Radiation (PAR) defines the range of the light spectrum that drives photosynthesis, covering wavelengths from 400 to 700 nm. It is the “menu” of light that plants feed on. From here, two measurements are crucial.

Photosynthetic Photon Flux (PPF) measures the total amount of PAR photons a luminaire emits per second, expressed in micromoles per second (µmol/s). It is the raw power of the engine. In this respect, high-quality 1000W HPS lamps still perform well, capable of generating a PPF of approximately 2,100 µmol/s ; meanwhile, the latest generation LEDs can reach from 2,700 and 3,300 µmol/s depending on the model and manufacturer.

The second metric, and the most important for the grower, is Photosynthetic Photon Flux Density (PPFD), which measures how many of those photons actually hit one square metre of the canopy per second (µmol/m²/s). This value tells us how much light “food” is reaching the plants and is the basis for any real performance comparison. And this is where system design, light distribution, and lamp height come into play.

Specialised power vs. total versatility

The next battlefield is the spectrum, where the philosophies of HPS and LED diverge dramatically. HPS lamps are famous for their characteristic yellow-orange light, with a spectrum dominated by wavelengths in the 550 to 750 nm range. This profile mimics the autumn sunlight, a natural signal that triggers a massive flowering response in cannabis. Science has shown that this abundance of red light is a potent stimulator of buds development, stimulating bulking, density, and weight.

The great advantage of modern LEDs is their versatility. Manufacturers can design panels with a full, customisable spectrum, providing blue light for vegetative growth, red light for flowering, and even supplementary wavelengths like UV rays to increase resin production. This turns LEDs into a kind of “Swiss Army knife” of Lighting, ideal for a full-cycle grow under a single light source.

The common argument positions the full spectrum of LED as superior, but this oversimplifies the strategy. Think of a toolbox: an adjustable wrench (the LED) is fantastic and versatile. However, for a specific task requiring maximum force, a professional will always choose a dedicated tool (the HPS for flowering). The supposed “limitation” of HPS (its fixed, predominantly red spectrum) is precisely its greatest strength. It doesn’t try to be good at everything; it is designed to be exceptional at one thing: delivering an avalanche of energy in the wavelengths that plants crave to produce large, heavy flowers.

Analysing cost, performance, and investment

Efficiency is the strongest argument in favour of LEDs, but the analysis must be comprehensive. The true measure of energy efficiency is Photosynthetic Photon Efficacy (PPE), which quantifies how many micromoles of PAR light a luminaire produces for every watt of energy it consumes (µmol/J). Here, high-end LEDs are the champions, with values that can reach 3.0 µmol/J , while high-performance 1000W HPS systems operate in a very effective range of 1.7 to 2.1 µmol/J. Although LEDs are numerically superior, it is a mistake to call HPS “inefficient”.

For the grower, the final metric is often yield per watt (g/W). Studies suggest that LEDs can achieve higher figures, often between 1.2 and 1.8 g/W, while HPS typically sits in the range of 0.8 to 1.2 g/W , although these values vary greatly depending on genetics, light intensity, and CO₂ supplementation. Nonetheless, HPS luminaires are legendary for producing buds of exceptional density and weight, with a “bag appeal” that many claim is difficult to replicate with LEDs.

The investment decision must also weigh both operational and capital costs. LEDs, with their greater efficiency, have a lower operating cost and a better long-term return on investment (ROI). However, the acquisition cost of a high-quality LED system capable of matching the intensity of a 1000W HPS is higher, often 2 to 3 times more expensive. Herein lies one of the keys to the persistence of HPS: it offers the highest photosynthetic power per pound of initial investment, a pragmatic decision for accessing high-intensity cultivation.

However, it is necessary to bear in mind that quality HPS lamps can maintain over 90% of their luminous flux for approximately 10,000 hours, whereas high-end LED panels exceed 50,000 hours of useful life before losing noticeable efficiency.

Radiant heat can be a drawback… or a great ally

The main criticism of HPS is its enormous heat output, which makes a robust ventilation system essential. However, this heat is not merely a waste product. For growers in cold climates, basements, or garages, the heat emitted by HPS can be an advantage, helping to maintain the optimal temperature and reducing the need for additional heating.

Even more important is the nature of this heat. HPS heat is primarily radiant (infrared), directly heating the leaf surfaces similarly to the sun, which drives plant transpiration—a vital process for nutrient uptake—while making it easier to maintain an optimal Vapour Pressure Deficit (VPD). In fact, it is not uncommon for growers who switch to LEDs, which run at much lower temperatures, to have to add heaters to compensate, reducing some of the energy savings. An HPS luminaire is not just a light source; it is an active environmental management tool.

When is a 1000W HPS system still a bright idea?

Synthesising these factors, clear scenarios emerge where a 1000W HPS luminaire is a logical choice in 2025. It is the tool for the flowering specialist looking to maximise bud weight and density, where the single, powerful light source of HPS provides exceptional penetration, ensuring that lower buds develop fully (although today, many high-intensity LEDs with suitable optics match or exceed uniformity/penetration with a correct layout).

It is also the choice for the grower with a controlled budget but high ambitions, who needs to get the maximum light intensity (PPFD) for their money. And it is the strategic choice for the grower in cold climates, who turns heat production into an operational benefit.

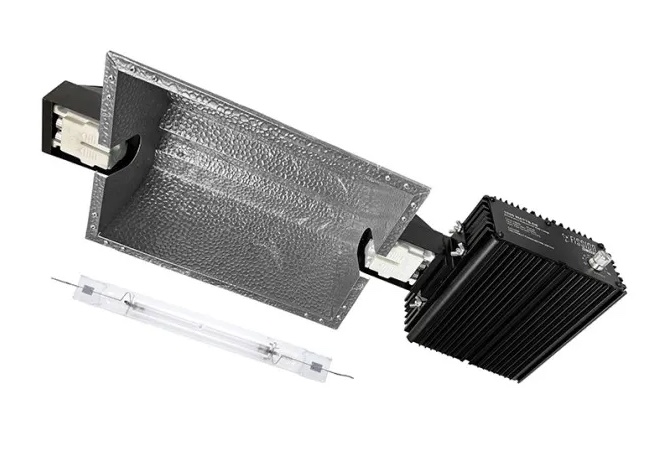

For growers who identify with these scenarios, The Pure Factory’s Fission 1000W HPS Luminaire Kit represents the ideal solution, embodying modern HPS technology optimised for high performance—a professional lighting tool for maximum efficiency and production, combining the robust Fission luminaire with the powerful Green Power Plus 1000W HPS DE 400V bulb.

This kit is conceived as an integrated system, where the Fission luminaire is designed to offer excellent light distribution, ensuring the intense energy from the bulb evenly covers the entire crop canopy. The Green Power Plus bulb, for its part, is a power source specific to the flowering phase, with a warm spectrum and a very high light output that maximises bud development and bulking. Together, they offer an easy-to-install solution that guarantees the reliability characteristic of The Pure Factory products.

Furthermore, it is crucial to consider the “legacy effect”. For decades, the most legendary and productive cannabis genetics were selected, bred, and perfected under HPS lights. A system like the Fission 1000W Kit recreates the exact spectral and thermal environment in which these strains are genetically predisposed to thrive, allowing their full potential to be unlocked in a way that a different light environment might not achieve.

A decision based on data, not trends

The narrative that LED has made HPS obsolete is an oversimplification that ignores the complexities of high-performance cultivation. While LED offers undeniable advantages, the investment decision cannot be based on a single metric. High-end HPS luminaires, like the Fission 1000W system, remain an exceptionally powerful tool. And in practice, many professional growers combine both technologies to leverage the best of each: the thermal and penetrative push of HPS alongside the spectral precision and efficiency of LED.

Because the “best” light is not a universal answer, but a strategic choice that depends on the budget, climate, and goals of each grower. For those focused on achieving maximum density in flowering with a controlled investment, a professional 1000W HPS system is not a relic of the past: it is a calculated, intelligent, and formidable tool for success.